Cutting

in two of the Swiss m.s. "Nyon"

an unusual salvage job

In november 1958 a job of very interesting character was carryied out by our tugs "Simson" and "Hector"and two British tugs, the "George V" and "Beamish". This was the salvage and the cutting in half of the Swiss motorship "Nyon", 4956 tons gross, which went aground in a dense fog off St. Abb's Head , Scotland and bottom was badly punctured. Attemps to refloat the vessel by the usual methods having proved unsuccessful, it was decided tosave the after part which contained the main and auxiliary machinery.

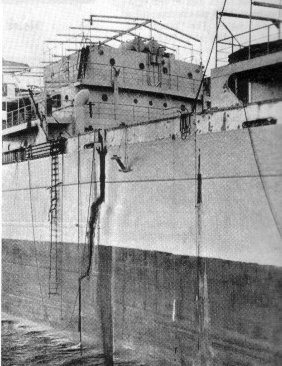

The m.s. "Nyon"aground in november 1985

The "Nyon" had given mayday signals and asked for tug assistance on saturday november 15th. 1958. The two British tugs were at first on the place of distress, but the master of the "Nyon" knew they needed havy salvage equipment and accepted our services on Lloyd's Open Form of Salvage Agreement. Our tugs "Simson" and "Hector", equipped with heavy pumps, divers etc. were proceeding and also two salvage inspectors were flying out to Edinburgh.

The Simson en Hector were proceeding to the Nyon

After arrival the tugs started immediately

to transfer salvage equipment to the "Nyon". Both connected and commenced

towing, but the "Nyon" did not move.

The ship was very badly leaking and much more pump was needed. More pumps, bottles of

oxygen and of gas, burning equipment and steelplates were brought on board the

"Nyon". Our men tried to close the holes by putting several tons of cement in

the bilges at low tide, but this was all destroyed by the working of the "Nyon".

The holds, I, II and III were tidal. All pumps were put into action but without

any effect.

In the opinion of all salvors it was impossible to save the whole ship. Each tide was

causing great deterioration to her structure and unless prompt steps were taken to sever

the valuable afterpart from the forepart the whole would soon become a total loss. On

november 21st. all our men commenced to move and make fast on the afterpart of the

"Nyon" all pumps, barrels of oil etc. from the forepart. They commenced also to

dismantle and remove all valuable instruments, such as the giro compass, the automatic

pilot, echo sounder, radio set, new ropes and wires, etc. etc.

The first operation was to weld the hatch bridle beams, and stiffen the deeptank bulkhead

and the tank top. At low tide it was possible to gain access to fractures in the deep tank

which were welded, and at the same time plates were fabricated for cement boxes. Flame

cutting was commenced when all water and oil pipes leading from the tunnel to the engine

room were cut and wood plugged. One half of the tunnel was welded first, the tunnel then

baled free of water and the second section plate fitted and welded.

During the morning of november 23rd. the burners started cutting

the hull on both sides. After some hours the sides of the hull had been cut right across.

After this all tugs - the two British tugs "George V"and "Beamis" were

contracted by Wijsmuller to assist the "Simson"and "Hector" - made

fast on the afterpart and started towing at full power, sheering from port to starboard as

much as possible in an endeavour to fracture the bottom plates, but without success.

During the morning of november 23rd. the burners started cutting

the hull on both sides. After some hours the sides of the hull had been cut right across.

After this all tugs - the two British tugs "George V"and "Beamis" were

contracted by Wijsmuller to assist the "Simson"and "Hector" - made

fast on the afterpart and started towing at full power, sheering from port to starboard as

much as possible in an endeavour to fracture the bottom plates, but without success.

Expectations that the rise and fall of the stern half with the tide would fracture the

keel plates also did not materialise. At low tide the cut opened to 2½ feet on the deck

and 1½ feet down the sites. As it appeared that in the calm weather conditions prevailing

it would be a long time even with the efforts of the tugs before the bottom plates parted

at the cuts, it was decided to obtain light explosives.

On november25th. the first of explosives and sand were lowered and exploded. More packets

were exploded, while the tugs were continually fast to the afterpart and kept on tugging.

The bottom plating still held. Further sets of explosives were placed and exploded. With

the rising tide on november 27th. the afterpart started working.

All tugs were now ordered to pull at full power and sheer to

starboard as much as possible. This caused the afterpart to come away about 10 degrees to

port of the forepart. The tugs kept pulling and sheering and with a light swell the

afterpart was lively so much that the starboard side opened and theafterpart came free.

The tugs pulled the afterpart slowly and carefully away from the coast into deeper

water and round St. Abb's Head in order to make course toward the Tyne. The afterpart of

the "Nyon" was not leaking and the stability and buoyancy were all right. On

november 28th. the tow arrived at Smit's Dockyard, North Shields.

All tugs were now ordered to pull at full power and sheer to

starboard as much as possible. This caused the afterpart to come away about 10 degrees to

port of the forepart. The tugs kept pulling and sheering and with a light swell the

afterpart was lively so much that the starboard side opened and theafterpart came free.

The tugs pulled the afterpart slowly and carefully away from the coast into deeper

water and round St. Abb's Head in order to make course toward the Tyne. The afterpart of

the "Nyon" was not leaking and the stability and buoyancy were all right. On

november 28th. the tow arrived at Smit's Dockyard, North Shields.

Some days later the forepart of the "Nyon" was fully dstroyed by a heavy

gale......!

On saturday, november 29th. the "Simson"and "Hector" went back

to Ymuiden, after two weeks hard working under difficuld circumstances the crew members

cleared this unusual salvage job, they going home, waiting for the next job.

The abandoned part after a winter galeAfter the successfully salvage of the afterpart the Owners of the "Nyon"decided to compleet the ship and lengthened the hull with 5½ yards. The contract for the reconstruction of the "Nyon" was awarded to the Dutch yard N.V. Boeles Shipyards at Bolnes and by the middle of 1959 the ship made her trials.

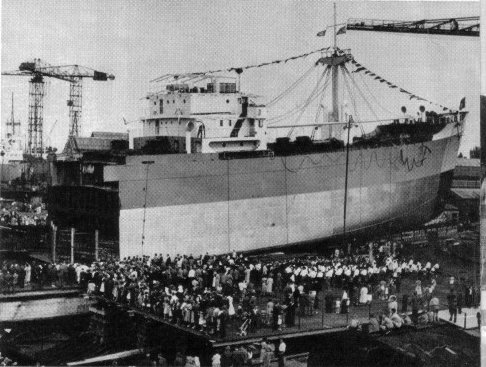

The new forepart being launched

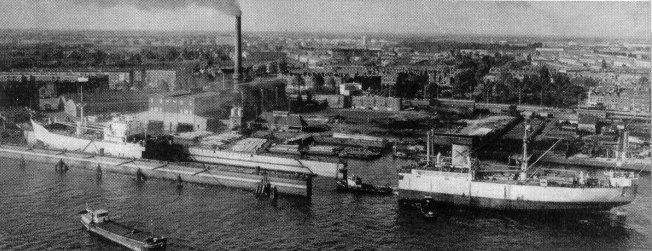

The two halves being put together in a floating drydock at N.V. Boeles Shipyards,

Bolnes

The renewed "Nyon" which had so much care and expertation, was'nt allotted a long live, on june 15th. 1962 at her voyage from Antwerpen to Montreal (Can.) the ship was perished after a collision in a dense fog with the Indian m.s. "Jalazad", at five miles of Beachy Head (Eng.)

![]()